Lubrication systems

Since 1987 Mecgi has successfully dealt with problems associated with lubrication and grease and oil dosing in machines, plants and systems used in a broad range of industrial sectors and fields. A broad and diversified clientele, combined with continuous in-depth research into innovative solutions, has ensured the acquisition of far-reaching expertise in the production of centralised grease and oil lubrication systems and automatic greasing systems.

Multi-brand Products and Assemblies

Mecgi distributes, installs and assembles lubrication products, offering guaranteed rapid delivery times. Maximum attention is afforded to pre and after-sales assistance worldwide. Mecgi is a partner with the best manufacturers in the sector, thus ensuring access to the most advanced knowledge in the international market for greasing products and centralised grease and oil lubrication systems. With more than 15,000 products and the ability to assemble components based on sophisticated technical specifications, Mecgi is the ideal point of reference both as a supplier of materials and for companies with centralised lubrication systems.

Design and Assistance

These are the companies that have chosen our centralised lubrication systems and Mecgi automatic greasing systems

The best companies choose centralised lubrication systems and automatic greasing systems, turning to proven experts for all their needs. Only the best centralised lubrication systems allow correct, regular, properly dosed lubrication, thus reducing costs and improving the life of machines.

That’s why centralised lubrication and automatic greasing systems have become an indispensable asset

50% of faults in plants are due to incorrect or insufficient lubrication. Grease and oil lubrication systems considerably reduce the number of breakages and offer many benefits: lubrication in hard-to-reach points, reduced wear and lower maintenance costs, extended average life of bearings and supports, perfect and continuous operation of machinery, reduced waste and lower lubrication costs.

Faults and breakages?

Faults and breakages?

50% of faults in plants are due to incorrect or insufficient lubrication. Grease and oil lubrication systems considerably reduce the number of breakages and offer many benefits: lubrication in hard-to-reach points, reduced wear and lower maintenance costs, extended average life of bearings and supports, perfect and continuous operation of machinery, reduced waste and lower lubrication costs.

Automatic greasing systems

Problems with bearings?

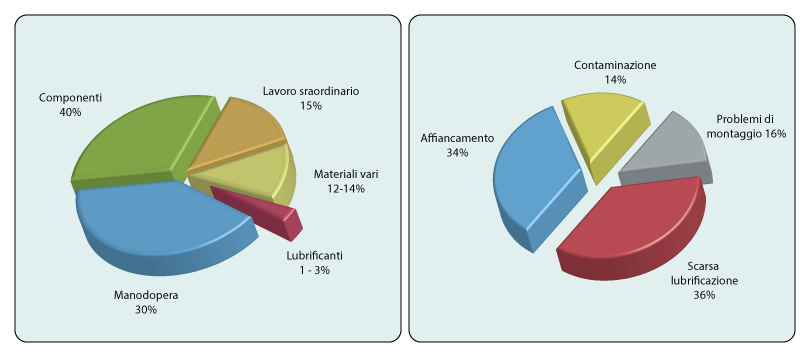

L’84% delle rotture e dei cedimenti dei cuscinetti derivano da scarsa lubrificazione, grasso contaminato e affaticamento dovuto a un innalzamento della temperatura. Gli impianti di lubrificazione centralizzata a grasso od olio sono una soluzione che prevengono le rotture e allungano la vita dei cuscinetti, lasciando macchinari sempre in produzione continua e in efficiente stato di funzionamento.

Automatic lubrication systems

Wasting too much lubricant?

In centralised lubrication systems grease is distributed where needed, when needed, in just the right amount. Special lubricant dosing units and recovery systems replace manual operations that are normally the cause of either over-dosage (when the maintenance technician inserts the grease) and under-dosage (when the grease is progressively consumed until no longer sufficient).

DO YOU KNOW HOW MUCH YOU'RE SPENDING?

Company maintenance costs

Premature bearing failure

Italiano

Italiano  English

English  Francais

Francais  Español

Español  Deutsch

Deutsch